OUR TUBE FORMING TECHNIQUES

le Bending

is a mechanical procedure for the plastic deformation of a tube or bar following a given radius and angle. It is used in many fields: plumbing, automotive industry, chemical industry and more.

Bending is also used as a generic term for tube forming… Bending is not a widespread industry.

There is no training course for bending; the trade can only be learnt by working for a bending company. When you bend a tube the exterior wall becomes thinner, the material lengthens and also becomes thinner. Not all tubes are bendable; the material must have a high enough elongation percentage. Contrary to the exterior wall, the interior wall thickens when the material is compressed. This phenomenon may cause folds to appear in the bend. This is one of the most common faults. To reduce thinning, we use pressure on the back of the tube called boosting. This practice is widely used with a short radius or with large diameter tubes.

To reduce folds we use a “wiper die” or a “smoothing clamp” that supports the inside of the tube during bending. Bending by rolling is a cold forming process for a tube or bar.

For complex pieces, bending tools are specifically adapted to the task.

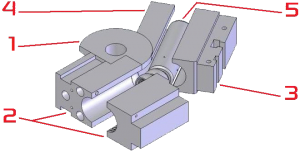

The aim is to work a part in three dimensions. Many materials are suitable including steel, stainless steel, copper, aluminium, brass and titanium. A tube is placed in the bending machine and tightened in a vice (2). Rotating around the roller axis (1), the tube is rolled according to the roller radius at the desired angle. A pressure die (3) absorbs the lateral forces which occur during forming and supports the tube’s exterior wall. The interior wall can be supported by a wiper die (4) to avoid the appearance of any folds in the material. Similarly, the inside of the tube is supported by a chuck (5) to avoid oval distortion of the tube. With these different elements we can obtain a very high quality part even for thin-walled tubes and for low bend radii. The forming process is not limited to bending round tubes. Oval tubes, flat and solid materials can also be formed as can four-edged sections and other open sections.